I have a Sapphire Plus printer which I have heavily modified (out of the box it is a piece of junk). After finally changing the mainboard and installing Klipper I got it to print reliably. Of course the next thing I wanted to do was print fast. It quickly became apparent that the E3D V6 hotend and the anemic 3010 fans severely limited said goal. So I got myself a Dragon HF hotend, a 5020 blower and printed this print head. From the get go I had massive problems with retraction, even after calibrating pressure advance the retraction towers I tried in Orca Slicer where all stringy messes. I kinda got it under control by severely slowing the retraction speed to 25mm/s with a 0.4mm retraction distance with nozzle wipe.

But now I’m sometimes getting these weird stringing artifacts on prints. Not on every print and not on every part, it’s just certain seams that get them. I’m currently printing with a 0.6mm CHT nozzle and a fresh roll of Elegoo PLA. Does anyone have any idea what could be the culprit? It ruined the finish on a few otherwise perfect prints.

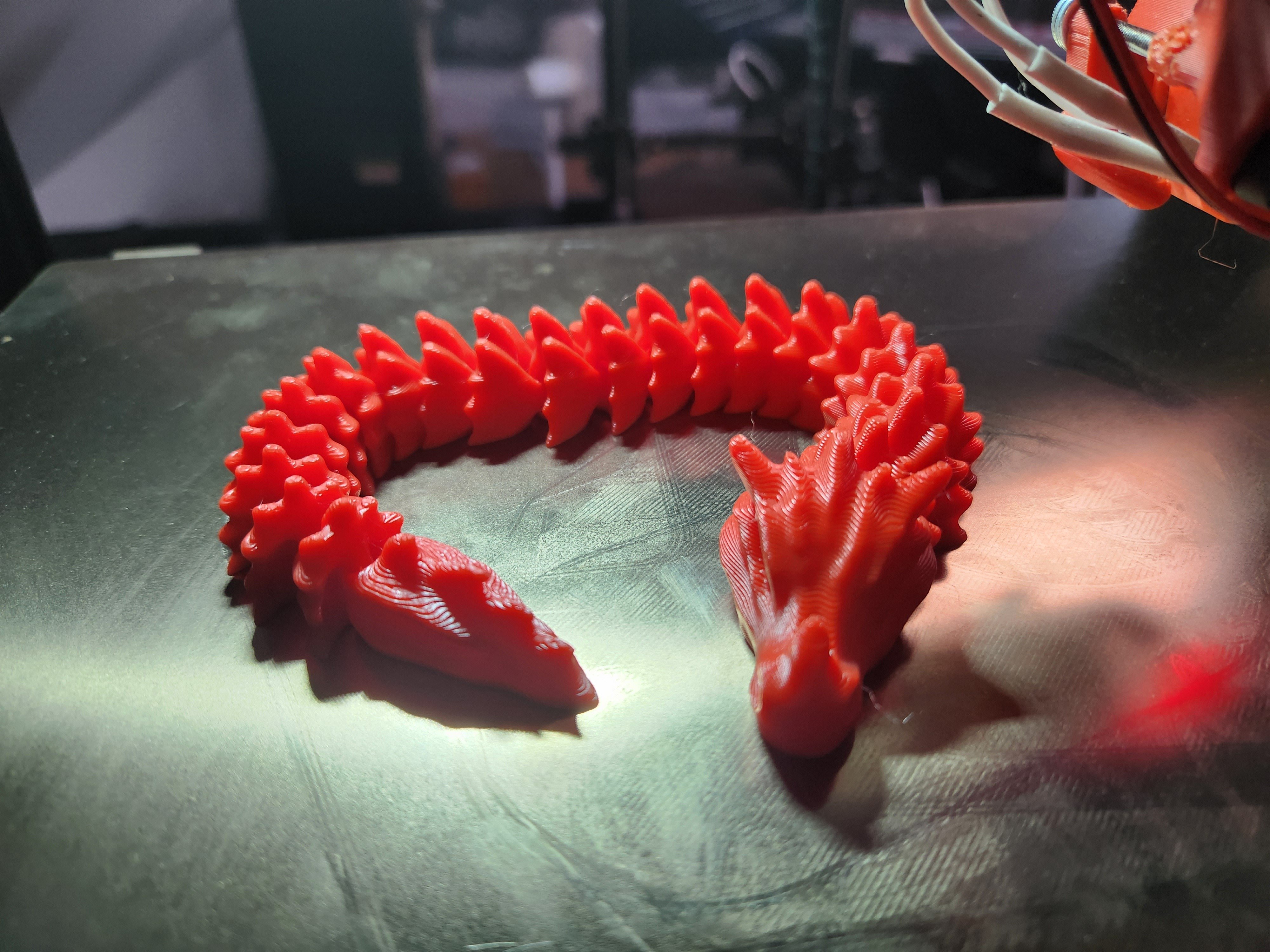

I even tried out this print:  since it has a lot of retractions, but of course that one turned out perfectly apart from a few tiny whisps.

since it has a lot of retractions, but of course that one turned out perfectly apart from a few tiny whisps.

That’s oozing. It’s unconnected to the previous section, but dripped out after the movement. The first blob attaches a little outside, the second blob on that one, building a 45 degree spire. (One crappy side effect is that for REALLY long moves, it can cause under extrusion at the restart.)

I have a Sovol SV06 Plus, also high flow. Same issue. I think it’s a weakness in all high flow because there’s FAR more filament in the melt zone. Lowering the temperature has helped a ton, but not solved it completely. I added a bigger fan on the hotend cooling section and it helped a lot, but not solved it. I’ve been told that upping my retraction to unreasonable levels should help, but I’ve not tried it. As in, I’ve got a direct drive, which usually has retraction less than 1mm, but to up it to 4mm. It’s my next experiment.

As an aside, if I could go back, I’d not get high flow option. I’d stick with the standard SV06.

Yeah, I should probably try it with a lower temperature, also got some PLA Meta filament in the post that might help

I’ve had those on PETG. It’s not really stringing, it’s a little tiny drop of filament that gets deposited further and further out as the nozzle makes travel moves. They clean up easily enough, so I’ve never worried about trying to deal with them.

That said, have you tried a lower temperature?

I call this oozing.

I actually had a hell of a time with petg with a 0.6mm cht on a dragon hf, ended up going back to a nozzle x because of it. I also found the bimetal cht nozzles really fragile, like 1.5 Nm torque from one of those slice preset wrenches and I’d still manage to have them shear off in the block after a few nozzle changes.

What did help was lowering the temps and being aggressive with the retraction speed (went up to 50mm/s if I recall), but even then the cht nozzles oozed a lot with petg, could have tuned a bit more but as I said I ended up going back to my other nozzles.

Kept the dragon though and actually swapped my mk3s over because I like that the block is fixed for nozzle changes and actually changed my voron to a dragon UHF that seems to be working well so far.

Yeah, I expected oozing and stringing with PETG, but not with PLA. For now I’ve switched back to the regular plated copper nozzle and don’t have anymore problems. The maximum flow rate went down from 40mm²/s to 25mm²/s but I can print a benchy in half an hour, so it’s still plenty fast

Some of the PLAs that are matte like this, are in my experience more prone to moisture absorption and all the related problems.

I had bad stringing with some modified PLA, and drying the filament completely cured the issue.

Yeah, this is plain PLA though and it prints fine on other printers. Maybe 200°C is too high of a temp

have you tried turning off z hop? I’ve found z hop leads to stuff like this

That depends for me on the height of the z-hop. Too much and the upward motion of the hop will pull filament out of the nozzle and worsen stringing. But that doesn’t happen to me when hopping a fraction of the layer height, then it helps to not deposit a blob along the way

I haven’t used Z-hop yet, due to some bad experiences with older printers, but I might have to give that a try

This can happen with under extrusion or over extrusion. You can try the auto towers plugin on Cura and print some Retraction Towers.

Already ran through all the flow rate, pressure advance, retraction towers and maximum flow rate calibrations in Orca Slicer

With a cht you have to be carefull of not retracting too much. I generally use 0.2 to 0.4 for direct drive. Higher travel accel can also help minimise strings.